For those who cherish the art of 3D printing, the Reynolds XZ-200 is more than just a machine—it’s a creative partner. To keep this partnership thriving, regular 3D printer maintenance is key. Not only does it ensure optimal performance, but it also extends the life of your printer, saving you from unexpected downtimes and costly repairs. Dive into these ten indispensable tips to keep your Reynolds XZ-200 running like a dream.

1. A Clean Slate: The Importance of a Pristine Print Bed

Imagine starting each print on a fresh canvas. After every creation, clean the build plate and bed with isopropyl alcohol and a lint-free cloth. This simple act prevents residue build-up, ensuring your next masterpiece adheres perfectly and reducing the chances of print failures.

2. Smooth Moves: Lubricating Rails and Lead Screws

Every 3–6 months, treat your linear rails and lead screws to a little TLC with PTFE or light machine oil. This reduces friction, ensuring smooth movements. For belts and pulleys, a quarterly spritz of silicone spray or a dab of lithium grease will do wonders. Don’t forget to retension those belts biannually to keep everything in harmony.

3. Precision Perfected: Calibrating Extruder and Bed Leveling

Monthly calibration is like tuning a musical instrument. Whether you prefer manual or sensor-based bed leveling, using a calibration cube ensures your prints hit the right notes every time. This regular check-up is vital for maintaining precision and reducing errors.

4. Out with the Old: Replacing Worn Nozzles and Filament Guides

Just as a painter replaces worn brushes, your printer needs fresh nozzles and filament guides every 50–100 print hours. This small investment can significantly boost print quality and extend nozzle life by up to 20%.

5. Tension Matters: Checking Belts and Pulleys

Quarterly inspections of belts and pulleys for fraying and proper tension are crucial. Correct tension ensures accuracy and helps prevent mechanical mishaps.

6. Breathe Easy: Cleaning Cooling Fans and Electronics

Dust is the silent enemy of electronics. Every 200–300 hours, use compressed air to clear dust from fans and electronics, preventing overheating and failures. For extra protection, house your printer in a WeatherProof Box.

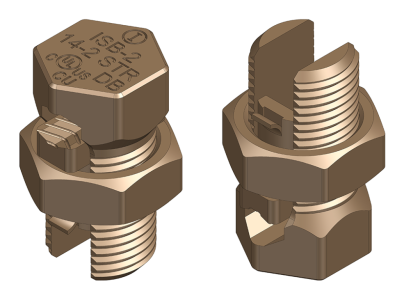

7. Power Up: Verifying Connections

Regularly check power and ground connections to ensure a steady “heartbeat.” Reliable connections prevent electrical issues. For peace of mind, consider using our Transformer Tank Type GTCL, Ground Rod Couplings, and Stainless Steel Grounding Rods.

8. Stay Updated: Firmware and Software Settings

Every six months, give your printer a digital refresh by updating its firmware and slicer software. Staying current ensures you benefit from the latest features and fixes.

9. Quality Assurance: Conducting Test Prints

Think of regular test prints as your printer’s health check-up. They catch potential issues early, resolving about 90% of problems before they become serious.

10. Be Prepared: Maintaining a Spare Parts Inventory

Having a stash of essential spare parts is like having a safety net. It minimizes downtime and keeps your creative flow uninterrupted. Check out our Mechanical Connectors Category for reliable components to keep on hand.

Conclusion

By embracing these maintenance tips, you’re not just preserving a machine—you’re nurturing a creative tool that enhances your projects and reduces service costs by 10–30% while slashing downtime by up to 50%. Download our maintenance checklist for a step-by-step guide, or contact us for premium lubricants and cleaning kits.