Ensuring Safety and Efficiency with Wire Nuts

Wire nuts are the unsung heroes of electrical work, offering a secure, UL-rated connection that prevents shorts and safeguards your projects. Whether you’re a seasoned electrician or learning how to use wire nuts as a DIY hobbyist, choosing the right connector is key. Let’s explore 10 types of wire nuts designed to meet diverse needs.

1. Standard Plastic Wire Nuts

- Construction: Durable plastic shell with internal metal coil (AWG #22–10, up to 600V).

- Applications: Ideal for indoor lighting, outlets, and receptacles. Compatible with #22 to #10 AWG copper or aluminum wires.

- Installation Tips: Strip ¾” of insulation, insert wires, twist 4–6 turns. Test torque around 8 in-lbs.

- Competitor Insight: Color codes (gray for #22–16 AWG, orange for #22–6 AWG) simplify selection.

- [Image placeholder: Standard plastic wire nut] Alt: Standard plastic wire nut

2. Winged Wire Nuts

- Construction: Plastic body with ergonomic wings and corrosion-resistant coil (#22–8 AWG).

- Applications: Great for large wire bundles and cramped spaces.

- Installation Tips: Use wings to apply steady torque; strip ¾” insulation, push and twist until snug.

- Rationale: Adds leverage when you need extra grip.

- [Image placeholder: Winged wire nut] Alt: Winged wire nut

- Volt Comp Butt Connector for comparing crimp vs. twist-on.

3. Waterproof Wire Nuts

- Construction: Plastic shell with silicone sealing insert (up to 600V).

- Applications: Outdoor lighting, pumps, landscape wiring.

- Installation Tips: Fill sealant chamber before twisting; ensure no gaps for moisture.

- Safety Note: Meets NEC requirements for damp locations.

- [Image placeholder: Waterproof wire nut] Alt: Waterproof wire nut

- Volt Comp Non-metallic Connector for outdoor cable terminations.

4. High-Temperature Wire Nuts

- Construction: Heat-resistant nylon or ceramic body with UL-rated coil (150°C max).

- Applications: Lighting fixtures, heating systems, appliances.

- Installation Tips: Strip ¾” insulation, twist fully, allow 10 minutes to cure before energizing.

- Competitor Insight: IDEAL’s high-temp models use deep-skirt design to protect against flash-over.

- [Image placeholder: High-temperature wire nut] Alt: High-temperature wire nut

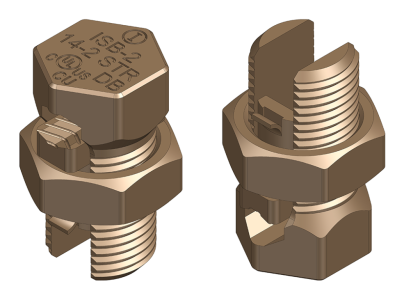

- Volt Comp Copper Split Bolt Connectors for high-temp grounding splices.

5. Push-In Wire Connectors

- Construction: Compact plastic body with metal spring cage (#22–14 AWG).

- Applications: Quick residential/commercial splices, LED light fixtures.

- Installation Tips: Strip exactly ½”–¾”, push straight in until stop; pull test to confirm.

- Benefit: Cuts installation time in half compared to twist-on.

- [Image placeholder: Push-in wire connector] Alt: Push-in wire connector

- Volt Comp Copper Compression “C” Crimp Connectors for permanent terminations.

6. Twist-On Wire Nuts

- Construction: Traditional plastic shell with threaded metal interior (#22–8 AWG).

- Applications: Versatile general-purpose connector for lighting and receptacles.

- Installation Tips: Align wire ends, twist clockwise until snug. Verify twist count per manufacturer.

- Pro Tip: Use a torque driver to ensure consistent tension.

- [Image placeholder: Twist-on wire nut] Alt: Twist-on wire nut

- Volt Comp Connectors for full line of twist-on options.

7. Color-Coded Wire Nuts

- Construction: Color-coded plastic shells to match AWG ranges (#22–6 AWG).

- Applications: Any job where quick size identification reduces errors.

- Installation Tips: Match nut color to wire gauge; strip and twist as standard.

- Competitor Insight: The Spruce’s color chart aligns gray, blue, yellow, red, orange nuts by capacity.

- [Image placeholder: Color-coded wire nut] Alt: Color-coded wire nut

8. Ceramic Wire Nuts

- Construction: High-temp ceramic body with stainless-steel coil (up to 200°C).

- Applications: Heaters, ovens, furnaces, industrial machinery.

- Installation Tips: Similar to standard nuts; allow cooling before re-torque.

- [Image placeholder: Ceramic wire nut] Alt: Ceramic wire nut

9. Flexible Skirt Wire Nuts

- Construction: Soft plastic skirt around the body for added insulation.

- Applications: Complex junction boxes, control panels.

- Installation Tips: Ensure skirt fully covers wires to prevent shorts.

- [Image placeholder: Flexible skirt wire nut] Alt: Flexible skirt wire nut

10. Heavy-Duty Wire Nuts

- Construction: Reinforced plastic or metal shell with heavy-gauge coil (#14–4 AWG).

- Applications: Industrial machinery, large motor connections.

- Installation Tips: Use high-torque driver; verify manufacturer’s torque spec (15–20 in-lbs).

- [Image placeholder: Heavy-duty wire nut] Alt: Heavy-duty wire nut

Conclusion: Mastering Wire Nut Selection and Installation

Choosing the right wire nut can make or break the safety and efficiency of your electrical project. From standard plastic to heavy-duty, each connector serves a unique purpose. Ready to level up your installations? Discover more in our installation guides and explore our full lineup of Volt Comp Connectors. How do you use wire nuts in your projects? Share your tips below!