Elevate Your Solar Experience: Mastering Grounding for Maximum Efficiency

Navigating the Solar Installation Maze

In the bustling world of solar installation, time is money. Delays can throw a wrench in your plans, affecting both project timelines and your return on investment (ROI). For many EPCs and rooftop PV installers, the stumbling block often lies in the intricate dance of grounding and bonding. According to the Photovoltaic System Grounding Study Report, these missteps can cost you days or even weeks of costly downtime.

The Solar Landscape: A Bright Future with Challenges

As the sun rises on the solar industry, more businesses and homeowners are turning to sustainable energy solutions. Yet, the path isn’t without its hurdles. Compliance with NEC PV Grounding Guidelines is a common stumbling block. Missteps like incorrect grounding conductor sizing or improper bonding jumper installation can lead to costly delays. To understand regional nuances, installers should also review local solar panel grounding requirements. But with the right approach, these challenges can be transformed into opportunities for efficiency.

Trends Shaping the Future of Solar Panel Installation

The race is on for faster commissioning in the solar world. As the industry accelerates, the impact of grounding delays becomes even more significant. A seamless solar panel setup is key to keeping projects on track and maximizing ROI. By tackling grounding and bonding issues head-on, installers can cut down on delays and boost installation efficiency.

Wisdom from the Experts: Grounding and Bonding Unveiled

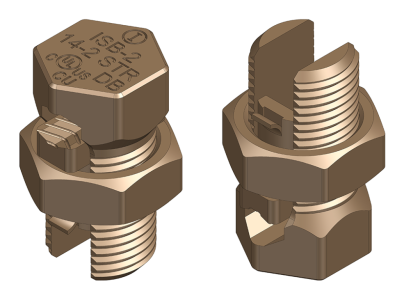

“Proper grounding and bonding are the backbone of PV system reliability,” says a leading expert from the Copper Development Association. High-quality, UL-listed connectors and strict adherence to NEC compliance are your best allies against costly setbacks. Volt Comp’s Copper Solar Lay-in Lugs and Copper Split-Bolt Connectors are crafted to meet these exacting standards, ensuring your installations are both reliable and efficient.

Your Go-To Guide for a Flawless Solar Panel Setup

- Secure Connections: Use Copper Solar Lay-in Lugs for robust connections.

- Torque Precision: Follow UL 486A–486B standards for Copper Split-Bolt Connectors.

- Terminal Ends: Install Copper Tubular Terminal Ends (VT series) with the right torque specs.

- Optimal Clamping: Utilize U-Bolt Road-to-Cable Clamps (SCE) with a torque of 12 Nm.

Take a leaf from the Springerville PV project case study, where a 4.6 MW project achieved rapid commissioning through savvy grounding techniques, including exothermic welding and strategic copper component use.

Fast-Track Your Solar Success

By embracing these practical grounding and bonding strategies, you can accelerate your rooftop solar ROI. Ensure your solar panel setup is not only efficient but also compliant with industry standards to sidestep delays and maximize your investment. For a deeper dive into Volt Comp products and their applications, explore our product catalog and take the next step in your solar journey.