Transforming the Future: Predictive Maintenance in Power Distribution

In the dynamic realm of electrical power distribution, predictive maintenance is not just a buzzword—it’s a revolution. As industries push the boundaries of efficiency and reliability, the art of predictive maintenance becomes a vital skill. Let’s explore how this innovative approach is reshaping the landscape of electrical power distribution networks, uncovering trends, insights, and practical steps to harness its full potential.

Navigating the New Power Landscape

The world of electrical power distribution is undergoing a seismic shift. A recent report by LTI Mindtree highlights a booming global market for predictive maintenance, fueled by the relentless pursuit of reduced downtime and superior operational efficiency. The fusion of cutting-edge technologies like IoT and AI is accelerating this growth, positioning predictive maintenance as the backbone of modern electrical systems.

Terms like condition monitoring and fault detection are no longer jargon but essential components of the predictive maintenance dialogue. These technologies empower real-time data analysis, enabling timely interventions and slashing the risk of unexpected failures.

Trends Shaping Tomorrow

A standout trend is the rise of IoT-enabled sensors for real-time monitoring. The MDPI Sensors review underscores how these sensors deliver crucial data, predicting equipment failures before they happen. Take, for example, the Rogowski sensors discussed in the IEEE paper, which provide precise current measurements, refining the accuracy of predictive models.

The impact of these trends is transformative. Transitioning from preventive maintenance to predictive maintenance allows companies to drastically cut maintenance costs and boost system reliability. This shift not only optimizes resource use but also prolongs the life of vital infrastructure.

Insights from the Pioneers

Industry leaders stress the importance of weaving predictive maintenance into existing systems. The ABB Ability™ white paper advocates for cloud-based platforms to enhance data accessibility and analysis, offering a comprehensive view of system health. This integration supports informed decision-making and strategic foresight.

Forward-thinking analysis reveals that companies investing in predictive maintenance technologies are better equipped to navigate future challenges. By adopting a data-driven mindset, these organizations can anticipate market shifts and maintain a competitive edge.

Practical Steps for Success

For businesses eager to dive into predictive maintenance, here are some actionable strategies:

- Embrace IoT Sensors: Deploy IoT-enabled devices for continuous monitoring and data collection.

- Harness Advanced Analytics: Use AI and machine learning algorithms to analyze data and foresee potential failures.

- Seamlessly Integrate Systems: Ensure smooth integration with existing infrastructure to fully leverage predictive maintenance benefits.

- Prioritize Training: Equip your team with the skills to interpret data and make informed decisions.

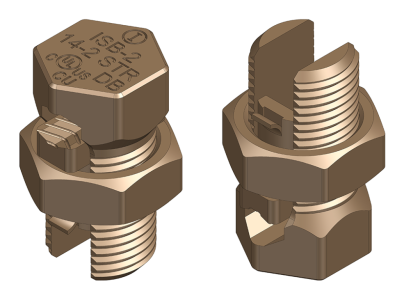

Consider exploring Ground Clamp Straight Ground Mount and Beam Clamps from Volt Comp to bolster your system’s reliability and efficiency.

A New Era of Maintenance

Predictive maintenance is more than a fleeting trend; it’s the future of electrical power distribution networks. By adopting this approach, companies can achieve unparalleled levels of efficiency and reliability. As the industry evolves, staying ahead with predictive maintenance will be key.

For further insights and products to enhance your maintenance strategy, visit Volt Comp’s Earthing & Lightning Protection Systems and discover their range of Crimping Type Copper Tubular Cable Terminal Ends.