Top 5 Electrical Component Manufacturing Trends Shaping 2025

Picture a world where electronics manufacturing is not just about speed and efficiency but also about sustainability and innovation. Welcome to 2025, a year where the electronics manufacturing industry is undergoing a remarkable transformation. Let’s dive into the top five trends that are revolutionizing this industry and shaping the future of electronics manufacturing.

A Glimpse into the Evolving Industry

The global electronics components market is on a trajectory to reach an astounding $4.86 trillion by 2025. With a compound annual growth rate (CAGR) of 2.11% from 2025 to 2029, the industry is poised for significant growth. The electronic components market alone is expected to soar from $428.22 billion in 2025 to $847.88 billion by 2032, boasting a CAGR of 10.3%. Industrial electrical components are also on the rise, with a market size of $57.2 billion in 2025 and a CAGR of 9.6% (Mordor Intelligence).

Yet, this growth is not without its challenges. The industry grapples with labor shortages, rising copper and zinc prices, supply chain volatility, and an urgent need for sustainability. As smart factories and Industry 4.0 become the norm, green manufacturing emerges as a critical focus.

The Trends Shaping Tomorrow

1. AI: The New Quality Control Maestro

Artificial Intelligence is making waves in electronics manufacturing, with its adoption expected to grow at a CAGR of 15–20% through 2025. AI-powered quality control is a game-changer, capable of reducing defects by 50%, tripling inspection speeds, and slashing labor costs by 40%. Volt Comp is leading the charge with its cutting-edge AI Vision Systems, setting new benchmarks in quality inspection.

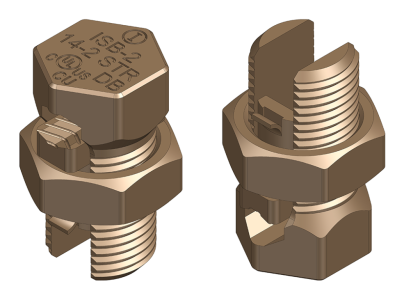

2. Crafting Custom Connectors with Additive Manufacturing

Additive manufacturing, especially 3D-printed electronics components, is experiencing a remarkable CAGR of approximately 24%. This technology slashes prototyping lead times by 60% and enables intricate designs and on-demand production. Volt Comp’s Custom Connector Design Services are a testament to the potential of this trend.

3. The Green Revolution in Copper & Zinc Sourcing

With copper and zinc prices on the rise, sustainable sourcing is more crucial than ever. Recycling efforts have surged by 20%, and closed-loop programs and certified low-impact mines are becoming the standard. Volt Comp’s Green Sourcing Programs underscore their commitment to sustainability.

4. The Smart Factory: IoT-Enabled Production Lines

By 2025, a quarter of electronics fabs are expected to be fully smart, thanks to IoT-enabled production lines. These lines offer real-time key performance indicators (KPIs), predictive maintenance that cuts downtime by 30%, and automated handling that reduces scrap by 15%. Volt Comp’s Smart Factory Solutions are at the forefront of this smart manufacturing revolution.

5. The Miniaturization Marvel: High-Density Connectors

The demand for microconnectors is skyrocketing, with a CAGR of 18% through 2027. This trend brings challenges like sub-millimeter tolerances and inspection complexity. Volt Comp’s Precision Microconnector Portfolio offers innovative solutions to these challenges.

Insights from Industry Pioneers

Industry leaders such as TradeAider, AssuredPartners, and Intelgic emphasize the pivotal role of AI in quality control. Aligning with IPC standards like IPC-A-610, IPC-6012, and IPC-1782 ensures compliance and quality. For more on sustainable sourcing, explore the IEA Global Critical Minerals Outlook 2025.

Navigating the Future: Tips for Consumers and End-Users

To stay ahead in the electronics manufacturing industry, consider auditing your supply chain for AI readiness and exploring 3D-printed prototypes. A compelling case study involves an OEM using machine-vision quality control to cut testing time by 30%.

The Road Ahead

In conclusion, the top five trends—AI-powered quality control, additive manufacturing, sustainable sourcing, smart IoT-enabled production lines, and miniaturization—are reshaping the electronics manufacturing landscape. We invite you to share your thoughts on these challenges or request a free prototype from Volt Comp to experience these innovations firsthand.