The Rise of Additive Manufacturing in Electrical Component Production

Over the past decade, additive manufacturing (AM), commonly known as 3D printing, has accelerated innovation in the electrical industry. From rapid prototyping to small-batch series production, AM allows manufacturers to deliver high-performance electrical connectors with unprecedented design freedom and material efficiency.

Design Flexibility and Material Advances

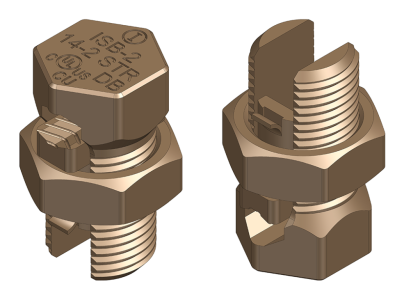

Innovators are leveraging new polymer and metal powders to optimize dielectric properties, mechanical strength, and thermal management. This opens doors to complex geometries that conventional machining cannot achieve, pushing the boundaries of what’s possible in electrical distribution and connection systems. Combined with our precision-engineered connector portfolio, engineers can tailor solutions for specialized applications.

Lightweight and Corrosion-Resistant Components

Weight reduction is critical for aerospace and portable equipment. Aluminum alloys and advanced polymers printed on demand deliver lightweight lug solutions without compromising conductivity. For harsh environments, zinc-based alloys provide corrosion-resistant electrical components that meet rigorous industry standards.

Eliminating Secondary Processes

Traditional terminals often require soldering or additional machining. With our solderless lug options, manufacturers can print complex lugs and connectors ready for installation straight off the build plate, reducing lead times and labor costs.

Key Industry Resources and Case Studies

- Hubs.com — On-demand manufacturing and AM services overview.

- Digital Engineering — Trends in 3D printing for electronics, with pilot case study insights.

- Stratasys Case Study — Implementation of AM in connector production and ROI analysis.

- 3D Printing Industry — Global market analysis and technology updates.

- Wohlers Report — Annual state of the 3D printing industry.

Future Outlook

As materials science and machine precision evolve, additive manufacturing will continue to disrupt electrical component supply chains. Manufacturers who integrate AM today will enjoy faster time-to-market, reduced inventory costs, and highly customized solutions that drive competitive advantage.