Transforming the World of Industrial Robotics

In the dynamic realm of cable manufacturing, keeping industrial robotics humming along without a hitch is not just a goal—it’s a necessity. Enter predictive maintenance, a revolutionary approach powered by AI that ensures these mechanical marvels remain online and efficient. By weaving predictive maintenance into their operations, manufacturers can dramatically cut down on downtime and boost productivity.

The High Stakes of Downtime

Imagine the clock ticking away as unplanned downtime grinds your operations to a halt. According to IIoT World and Pingdom, each hour of downtime can cost a staggering $260,000. This eye-watering figure underscores the pressing need for effective maintenance strategies. Predictive maintenance steps in as a savior, using data-driven insights to foresee and prevent equipment failures before they disrupt your workflow.

Riding the Wave of Key Trends

Harnessing the Power of Machine-Learning Analytics

At the heart of predictive maintenance lies machine-learning analytics. The Siemens ROI Report reveals that companies embracing these analytics enjoy a 200% return on investment, 30% less downtime, and 25% lower maintenance costs, translating to annual savings of $1 million. These numbers highlight the transformative power of machine-learning in maintenance strategies.

The Game-Changer: IoT Sensor Networks

IoT sensor networks are reshaping how manufacturers keep tabs on equipment health. As noted by MachineMetrics and Groundup.ai, embedding IoT sensors in machinery enables real-time data collection and analysis. This innovative approach has slashed unplanned stops in cable pullers and crimpers by 40%, proving the effectiveness of IoT in predictive maintenance.

Predictive Algorithms: The Crystal Ball of Maintenance

Predictive algorithms are another vital piece of the puzzle. Microchip Technology’s case study shows that by leveraging cloud-based machine-learning analytics, they achieved a 50% reduction in downtime and a 20% boost in overall equipment effectiveness (OEE) in robotic assembly lines. These algorithms empower manufacturers to foresee and tackle potential issues proactively.

Insights from the Industry’s Visionaries

Industry experts are unanimous: the future of manufacturing is intertwined with predictive maintenance. “The integration of AI and IoT in maintenance strategies is not just a trend but a necessity,” asserts a leading industry analyst. As technology continues to evolve, the potential for further reducing downtime and enhancing efficiency is boundless.

Your Roadmap to Implementing Predictive Maintenance

- Begin by integrating IoT sensors into critical machinery to capture real-time data.

- Employ machine-learning analytics to interpret this data and anticipate potential failures.

- Invest in robust predictive algorithms to refine decision-making processes.

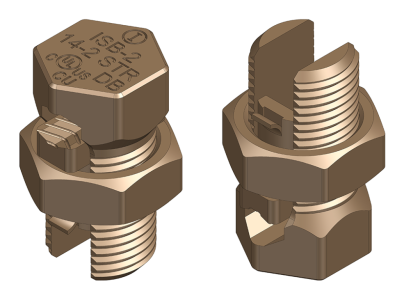

- Explore Volt Comp’s array of products to bolster your maintenance strategy, including Mechanical Connectors, Beam-Clamps, and Crimping Type Copper Tubular Cable Terminal Ends.

- Ensure proper grounding with Stainless Steel Grounding Rods and Ground Rod Couplings.

Embrace the Future of Maintenance

Predictive maintenance is not just a buzzword—it’s a game-changer for the cable manufacturing industry, ensuring that industrial robotics remain perpetually online. By adopting AI-driven strategies, manufacturers can significantly reduce downtime and enhance operational efficiency. Step into the future of maintenance today and explore the comprehensive solutions offered by Volt Comp to stay ahead in the competitive manufacturing landscape.