Unlocking the Secrets of Copper Split-Bolt Connectors for Reliable Grounding

Imagine a world where your electrical systems are not just functional but also safe and efficient. The key to achieving this lies in the often-overlooked heroes of electrical systems: copper split-bolt connectors. These small yet mighty components are essential for ensuring reliable electrical grounding. Let’s dive into the art of selecting, installing, and troubleshooting these connectors to enhance the safety and efficiency of your electrical installations.

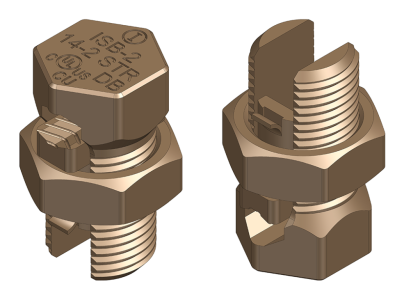

The Marvel of Copper Split-Bolt Connectors

Copper split-bolt connectors are the unsung champions of electrical systems, designed to securely join multiple conductors. Crafted from high-conductivity copper or sometimes bronze alloy, these connectors are vital for efficient grounding. Proper grounding is not just a technical requirement; it’s a safety imperative that prevents electrical faults and ensures compliance with the UL486A Standard and the NEC Grounding Requirements Guide.

Your Toolkit for Success

Before embarking on your installation journey, gather these essential tools and materials:

- Torque wrench

- Wire strippers

- Cleaning tools

- Insulating tape

- Copper Split-Bolt Connectors

- Conductors

For detailed product specifications and UL/CSA ratings, explore our Copper Split-Bolt Connectors.

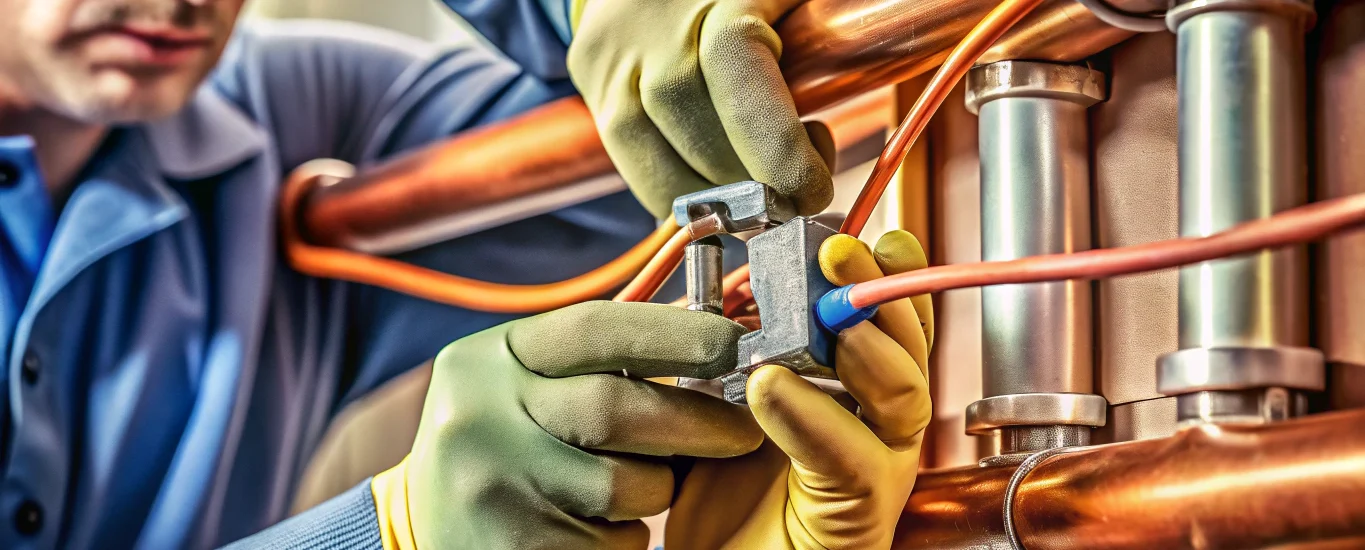

Mastering the Art of Installation

Choosing the Perfect Connector

The first step is selecting a connector that matches your conductor’s size and material. Consult the torque chart from ILSCO FORM-165 to ensure a perfect fit.

Preparing Your Conductors

Strip away the insulation and clean the copper surfaces to remove any oxidation. This step is crucial for a solid connection.

Bringing It All Together

Position the conductors within the connector and tighten them to the specified torque. For instance, use 25–40 in-lb for AWG sizes, 165 in-lb for #8–#4, and 275 in-lb for #2.

The Final Touch

Double-check the torque and test for continuity to confirm a secure connection.

- Opt for corrosion-resistant variants to extend the lifespan of your connections.

- Avoid overtightening to prevent damage.

- Label ground points for easy identification.

Troubleshooting: Turning Problems into Solutions

Loose Connections

If you encounter loose connections, retorque the connectors and inspect the surfaces for cleanliness.

Battling Corrosion

Combat corrosion by using Copper Split-Bolt Connectors – Tin Plated and applying an anti-oxidation compound.

Frequently Asked Questions

What torque values should I use for different conductor sizes?

Refer to product specifications: 20–50 in-lb (KS-CP), 25–40 in-lb (ILSCO), 165 in-lb (SEL), 275 in-lb (#2 AWG).

Can I use split-bolt connectors for direct burial?

Yes, when UL listed for direct burial. Always check product ratings.

The Path to Reliable Grounding

In essence, the journey to reliable electrical grounding begins with selecting the right copper split-bolt connector, adhering to torque specifications, and effectively troubleshooting common issues. For a comprehensive range of grounding solutions, visit Volt Comp.