Imagine a world where your electrical systems hum along perfectly, every connection as secure as a vault. This isn’t just a dream—it’s achievable with the right electrical connectors. In this guide, we’ll explore how to choose the perfect connector for your project, taking into account factors like conductor material, current rating, and application. We’ll also delve into performance criteria, compliance standards, and the delicate balance between cost and performance.

The Art of Connection: Understanding Electrical Connectors

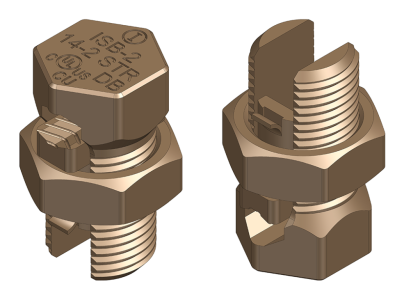

Electrical connectors are the unsung heroes of any electrical system, ensuring that power flows smoothly and efficiently. From mechanical to split-bolt to tubular connectors, each type has its own role, whether it’s for power distribution, grounding, or substation connections. When choosing, consider key performance criteria like conductivity and corrosion resistance. And remember, compliance with standards such as UL 486A/B and IEEE 837-2014 is non-negotiable for safety and reliability. For a deeper dive into connector theory, see Burndy’s Connector Theory and Application.

Equipping Yourself: Tools and Materials for the Job

Before you embark on your connector journey, arm yourself with the right tools. Crimping tools and torque wrenches are essential, as are a variety of connector types and conductor materials. For top-notch performance, consider Volt Comp Mechanical Connectors, Copper Split Bolt Connectors, and Copper Tubular Cable Terminal Ends. For splice selection across cable systems, refer to the 3M White Paper.

Navigating the Connector Maze: A Step-by-Step Guide

-

Understanding Your Project’s Needs

Start by getting to know your project’s specific requirements. What conductor material are you working with? What’s the current rating? What environmental conditions will the connectors face? These questions will steer you toward the right connector type and material. For extra guidance, see NorComp’s selection guide.

-

Exploring Connector Types

Dive into the world of connectors and compare options like mechanical, split-bolt, and tubular connectors. For an overview of industry offerings, visit TE Connectivity. For example, Copper HT Lugs with 2 Holes are known for their excellent conductivity and durability.

-

Prioritizing Performance and Compliance

Make sure your chosen connectors meet performance standards like UL 486A/B, which tests for pull-out strength and temperature-rise, and IEEE 837-2014, which focuses on mechanical pull/torque and environmental durability.

-

Balancing Cost and Performance

Perform a cost-vs.-performance analysis using Total Cost of Ownership (TCO) tables and competitor comparison charts. This ensures you’re getting the best bang for your buck.

Troubleshooting: Common Problems and Their Solutions

Even the best-laid plans can go awry. Common installation errors include over- or under-crimping and insulation damage. To troubleshoot, use field reliability metrics and customer case studies to identify and resolve issues. Proper installation and maintenance are key to enhancing connector reliability.

The Final Word: Ensuring System Reliability

Choosing the right electrical connector is vital for system reliability. By weighing factors like performance criteria, compliance standards, and cost-vs.-performance, you can ensure your electrical systems run smoothly. We recommend considering all these factors and opting for Volt Comp products for the best results.

Dive Deeper: Further Reading and Resources