In the world of electronics, where precision is paramount, the art of PCB design stands as a cornerstone. For those who revel in the intricate dance of circuits and signals, optimizing your PCB layout for maximum signal integrity is not just a task—it’s an art form. Join us as we explore the essential tools, materials, and an eight-step process that will transform your PCB design into a masterpiece of efficiency and reliability.

The Symphony of Signal Integrity

Imagine a symphony where every note is clear and harmonious. That’s what signal integrity brings to PCB design. It’s the guardian of data fidelity, ensuring that your high-speed layouts perform flawlessly without the disruptive interference of jitter or electromagnetic interference (EMI). In the realm of electronic devices, maintaining signal integrity is akin to ensuring the orchestra plays in perfect harmony, preventing data loss and system malfunctions.

The Artisan’s Toolkit: Essential Tools and Materials

Every artist needs their tools, and PCB manufacturing is no different. To achieve optimal signal integrity, the right tools and materials are your best allies. Picture yourself wielding EDA tools like Cadence Allegro, Altium Designer, and Mentor HyperLynx—each a brushstroke in your design masterpiece. High-TG FR-4 and Rogers laminates are your canvas, while Time Domain Reflectometers (TDR) and Vector Network Analyzers (VNA) serve as your critics, ensuring every detail is perfect.

- EDA Tools: Cadence Allegro (Cadence signal integrity basics), Altium Designer, Mentor HyperLynx

- Materials: High-TG FR-4, Rogers laminates

- Test Equipment: TDR, VNA, spectrum analyzer

The Eight-Step Layout Masterclass

1. Crafting the Layer Stack-Up

Begin your journey with a meticulously planned PCB stack-up. This is your foundation, controlling impedance and reducing EMI. [Insert Stack-Up Diagram] (EMA-EDA best practices).

2. The Art of Impedance Calculations

Precision is key. Use tools like Keysight ADS or Saturn PCB to calculate impedance with the accuracy of a master craftsman, ensuring your signals flow seamlessly (RunTime Rec layout optimization).

3. The Dance of Differential Pair Routing

Route your differential pairs with the grace of a ballet dancer, maintaining consistent spacing to minimize crosstalk. [Insert Differential Pair Geometry Diagram] (Crosstalk elimination techniques in Altium Designer).

4. The Via Strategy

Strategize your vias to minimize signal reflection and loss. Back-drilled vias are your secret weapon, reducing unwanted stubs in high-speed designs. (NASA high-speed PCB guide).

5. Return Path Optimization

A clear return path is your ally against ground bounce. Visualize it as a well-trodden path in a serene garden, guiding your signals home. [Insert Return Path Illustration] (ProtoExpress HDI PCB design tips).

6. Mastering Termination Techniques

Apply termination techniques with the finesse of a seasoned artist, matching impedance and reducing signal reflections. Series and parallel terminations can be referenced from Cadence signal integrity basics.

7. The Battle Against EMI

Identify and mitigate EMI sources with the precision of a detective, using spectrum analyzers and shielding techniques to maintain signal purity.

8. The Final Validation

Validate your design with TDR and VNA, ensuring it meets the highest standards of signal integrity. This is your final brushstroke, completing your masterpiece.

Troubleshooting: The Artist’s Touch

Even the best artists face challenges. Address common issues like ringing and crosstalk by adjusting trace lengths and employing decoupling capacitors. [Insert Ringing Waveform Diagram]

Curiosities and Conundrums: FAQs

What is the ideal spacing for differential pairs?

Maintain a spacing of three times the trace width to minimize crosstalk.

How to choose between microstrip and stripline?

Choose microstrip for surface layers and stripline for internal layers, much like selecting the right brush for your canvas.

When should back-drilled vias be used?

In high-speed designs, back-drilled vias are your allies against stub effects.

How many decoupling capacitors should be placed near an IC?

Place at least one decoupling capacitor per power pin, ensuring stable power delivery.

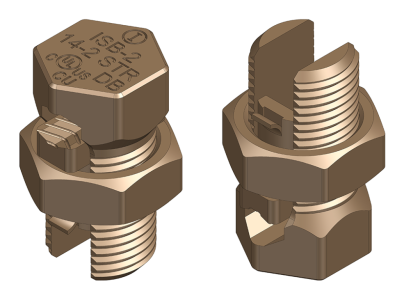

Reference Design and Product Call-Out

For a practical example of optimized PCB design, download the Volt Comp High-Speed Reference PCB. Enhance your creation with: