A New Era in Cable Tray Systems

The cable tray market is undergoing a fascinating transformation. While metal trays are projected to reach USD 3.18 billion by 2025, composite cable trays are rapidly gaining ground. With an expected growth from USD 253.48 million in 2019 to USD 696.78 million by 2032, these trays are becoming the go-to choice for those seeking lightweight, corrosion-resistant, and sustainable wire management solutions.

The Shift Towards Efficiency and Sustainability

Comparing Performance Metrics

Composite cable trays, especially those crafted from Fiber Reinforced Plastic (FRP), are redefining efficiency. They offer remarkable corrosion resistance and sustainability, making them perfect for challenging environments. Their lightweight design not only speeds up installation but also cuts down on labor costs, boosting overall efficiency.

Embracing Eco-Friendly Solutions

In a world increasingly focused on sustainability, composite cable trays shine. These UV-stable composite trays are not only robust but also help reduce the carbon footprint of industrial projects, aligning perfectly with global sustainability goals.

Insights from the Experts

The Power of Composite Materials

FRP materials boast an impressive strength-to-weight ratio, making them versatile for various applications. Their non-conductive nature enhances safety, a crucial consideration in industrial wiring infrastructure.

Meeting Safety and Compliance Standards

Safety is non-negotiable. Composite cable trays adhere to NEC, IEC, and NEMA standards, ensuring they are safe and reliable across diverse environments. Their fire-resistant properties further bolster safety, making them a top choice for many industries.

Real-World Applications and Success Stories

EPP Composites: A Testament to Versatility

EPP Composites has demonstrated the versatility and efficiency of composite cable trays in numerous projects, proving their worth in effective wire management.

Transforming the Gulf-Coast Chemical Plant

A standout case study involves the Gulf-Coast chemical plant, where composite cable trays replaced traditional metal ones. This retrofit led to a significant reduction in maintenance costs and enhanced system reliability.

The ROI Advantage

While the initial investment in composite cable trays may be higher, the long-term savings in maintenance and replacement costs are undeniable. Their durability and low maintenance needs contribute to a favorable ROI, making them a smart investment for facility managers.

Navigating the Transition: Tips for Facility Managers

- Assess your facility’s specific needs to select the right tray type.

- Weigh the long-term benefits and ROI against initial costs.

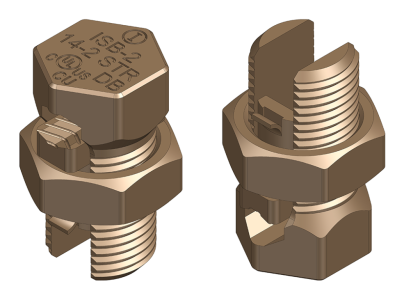

- Leverage internal resources like Volt Comp’s non-metallic connectors and clamp backs to optimize your cable management system.

Explore Volt Comp’s cable terminal products and earthing and lightning protection systems for comprehensive solutions.

The Future of Wire Management

Composite cable trays are not just a trend; they are revolutionizing wire management in structured cabling systems. With their superior performance, sustainability, and adherence to safety standards, they are the ideal choice for modern industrial applications. Facility managers are encouraged to embrace these benefits and explore the innovative solutions offered by Volt Comp to elevate their wiring infrastructure to new heights.