The Heartbeat of Electrical Systems

In the world of electrical systems, wire connectors are the unsung heroes that ensure continuity, safety, and reliability. Without the right connection, even the most powerful circuits can fail. This guide dives deep into the art of selecting, installing, and maintaining wire connectors to keep your systems running smoothly.

Types of Wire Connectors

Wire connectors come in a variety of designs, each serving a unique purpose:

- Copper Tubular Cable Terminal Ends – Ideal for high-conductivity applications, these crimping type copper tubular cable terminal ends provide a secure, low-resistance connection. (Wiring Depot)

- Specialized Copper Tubular Ends – A premium variant with enhanced corrosion resistance, see this product for more details. (IDEAL Industries)

- Spade Terminals – Quick-disconnect bronze spade terminals are perfect for panel and chassis wiring; check our bronze spade terminal. (Core Electronics)

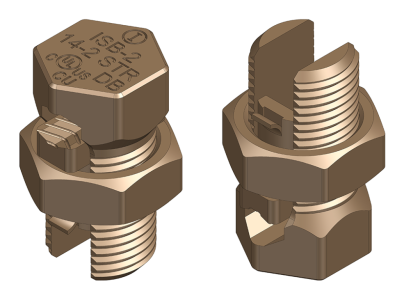

- Mechanical Connectors – Versatile and reusable, browse our mechanical connectors for various applications. (Solderstick)

- Earthing & Lightning Protection Systems – Critical for safety, explore earthing and lightning protection connectors.

Choosing the Right Connector

Selecting the correct connector depends on several factors:

- Wire Gauge: Match connector capacity to the conductor size to avoid overheating.

- Material Compatibility: Use copper connectors with copper conductors to minimize galvanic corrosion.

- Environmental Conditions: For outdoor or corrosive environments, choose connectors with appropriate plating or seals.

- Current Rating: Verify the connector’s amperage rating exceeds your circuit’s maximum load. (Pacer Group)

Installation Best Practices

Proper installation ensures reliable connections:

- Strip Length: Expose only the recommended length of insulation to prevent short circuits.

- Crimping Tools: Use calibrated crimping tools to apply consistent pressure. If you’re using our tubular terminals, ensure the tool matches the terminal size.

- Inspection: After crimping, inspect for uniform deformation and firm wire retention.

- Environmental Sealing: Apply heat-shrink tubing or sealant in moist or outdoor applications.

Maintenance and Testing

Regular checks prolong connector life and system safety:

- Perform periodic torque tests on bolted connections.

- Check for signs of corrosion or discoloration.

- Use thermal imaging to detect hotspots in critical circuits.

Frequently Asked Questions

How do I choose the right wire connector for my application?

Consider the conductor size, current rating, material compatibility, and environmental factors. Always verify ratings and use quality tools for installation.

What is the proper way to crimp a connector?

Strip the insulation to the specified length, insert the conductor fully, then apply a calibrated crimping tool perpendicular to the barrel until the connector is uniformly compressed.

Can I reuse wire connectors after removal?

Mechanical and screw-on connectors can often be reused if undamaged, but crimped and soldered connections should be replaced to ensure safety and reliability.