In the dynamic world of electrical systems, the quest for reliable and efficient solutions is more pressing than ever. Enter tin-plated copper connectors—a revolutionary development that’s reshaping the landscape of power distribution. As industries pivot towards sustainability and durability, these connectors are proving to be a pivotal innovation. Let’s explore how they’re transforming electrical connectivity and paving the way for a greener future.

For a deep dive into tin plating applications, check out Tin Plating of Busbars – Benefits and Advantages.

Battling the Elements: How Tin-Plating Fights Corrosion

Corrosion has long been the nemesis of electrical connectors, especially those braving the elements in overhead lines and buried applications. These harsh environments can lead to oxidation and, ultimately, connector failure. But there’s good news: tin-plating on copper connectors is a game-changer. It significantly boosts corrosion resistance, extending the lifespan of these vital components and slashing maintenance costs. This means fewer disruptions and a more reliable power supply—music to the ears of utility companies everywhere.

Learn more about tin plating for copper busbars: Tin Plating of Copper Busbars – What You Need to Know.

Why Tin-Plating is a Game-Changer

So, what makes tin-plating so special for copper connectors? For starters, it enhances oxidation resistance, which translates to a longer lifespan and less frequent maintenance. This is a win-win for utility companies, reducing the need for costly service calls and improving overall efficiency. Plus, the superior conductivity of tin-plated connectors ensures optimal power distribution, making them a must-have in today’s advanced electrical systems.

Dive into the science behind tin-plated copper in marine environments: The Science of Tinned Copper in Marine Environments.

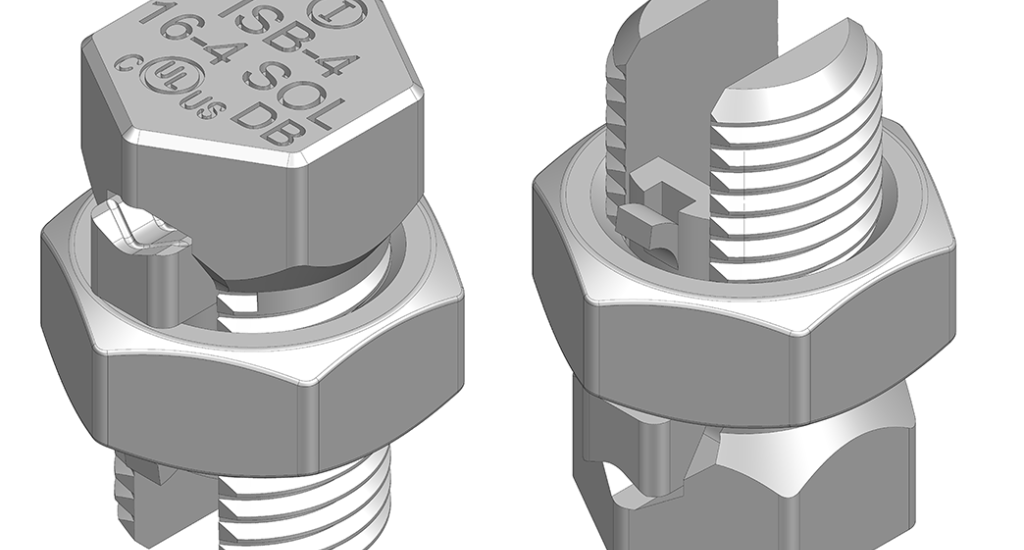

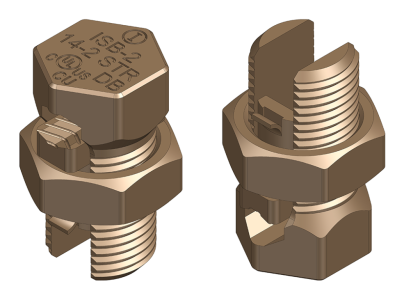

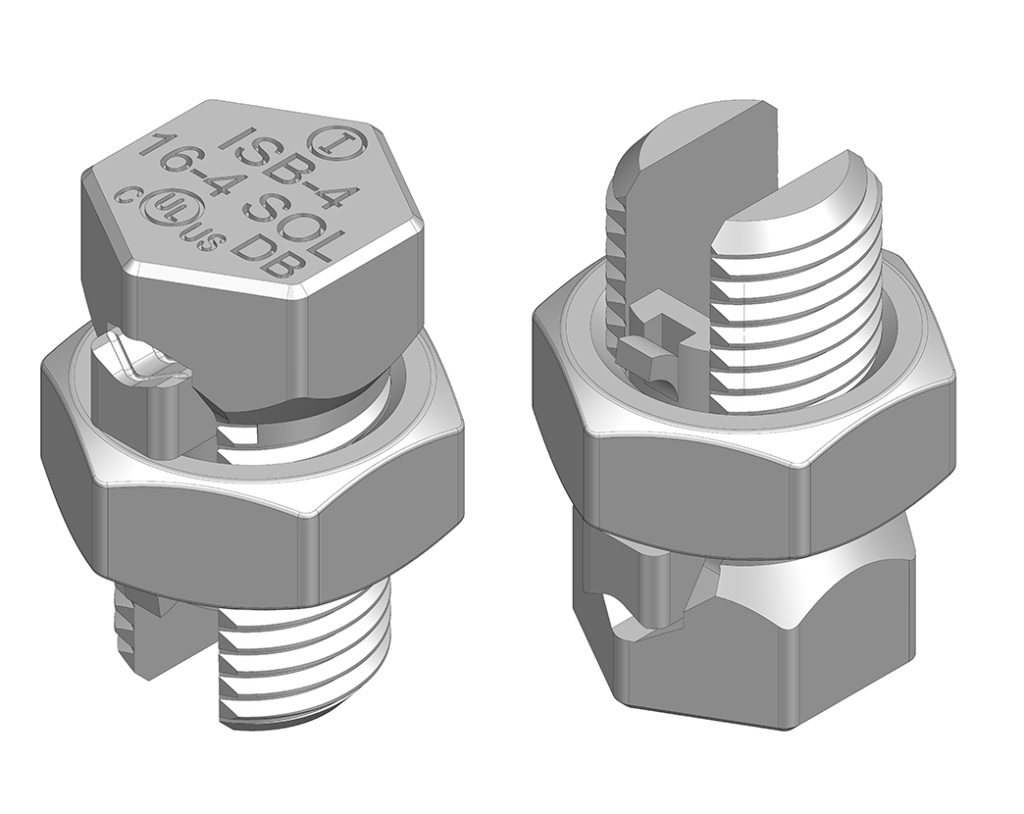

Curious to see these benefits in action? Check out our Copper Split-Bolt Connectors – Tin Plated and Spade Terminal – Tin Plated.

Sustainability: The Green Edge of Tin-Plated Connectors

In a world increasingly focused on sustainability, the environmental benefits of tin-plated copper electrical connectors are hard to ignore. By reducing scrap and minimizing replacements, these connectors help lower the carbon footprint of electrical systems. A recent case study highlighted a 30% reduction in material waste when switching to tin-plated options, underscoring their role in achieving global sustainability goals. It’s clear: these connectors are not just about performance—they’re about preserving our planet.

However, it’s important to consider potential drawbacks: Potential Issues with Tin-Plated Conductors and tinned vs bare copper lugs.

Volt Comp’s Cutting-Edge Solutions

Leading the charge in this innovative field is Volt Comp, with its Type SW tin-plated connectors. Engineered to meet the highest standards of performance and safety, these connectors are CSA/UL certified and boast impressive kV ratings. They’ve been successfully deployed in a variety of applications, proving their versatility and efficiency.

Explore our top solutions, including the Butt Splice Connector, Crimping-Type Copper Tubular Cable Terminal Ends, and our Copper Compression C Crimp Connectors.

Insights from the Experts

“The adoption of tin-plated copper connectors is a pivotal step towards achieving sustainability in utilities. Their durability and reduced environmental impact make them a preferred choice for future-proofing electrical systems.”

— Utility Sustainability Officer

A New Chapter in Electrical Connectivity

As we look to the future, tin-plated copper electrical connectors stand out as a beacon of innovation in the field of electrical connectivity. By tackling corrosion and offering significant environmental benefits, they’re set to become the gold standard in power distribution systems. For industries committed to sustainability and efficiency, embracing these connectors is a strategic move towards a more reliable and eco-friendly future.

Learn about advanced insulated bus bars: Explore the Wonders of Tin-Plated Insulated Bus Bars.